Food industry

AGVs are vital in the food industry, enhancing efficiency, cutting labor costs, and ensuring safe transportation. They are used in warehouses, distribution centers, and manufacturing facilities.

Established in 1977, Solving is a leading AGV manufacturer, specializing in automated handling systems for heavy loads, and has been supplying customized handling solutions also to the food industry. Our automated systems, Solving AGV Movers, have been installed for the continuous handling of palletized food products and frozen goods.

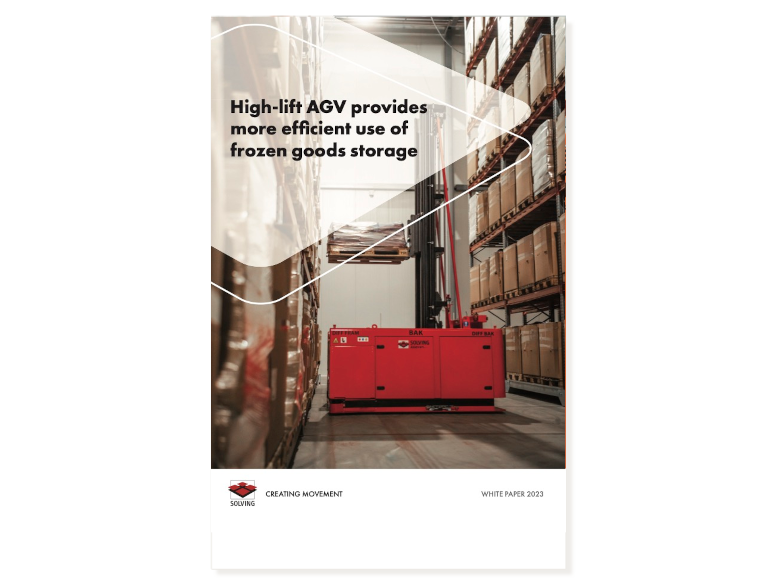

High-lift AGV provides more efficient use of frozen goods storage

Learn how we made it possible for this high-quality food producer to automate their frozen goods storage for meat products with a high-lift AGV

Automated handling was the smoothest alternative for transportation from point A to B in a -20 degree cold storage, and our personnel can be utilized for other tasks instead

Erik Björkskog, head of the freeze process at Snellman.

AGVs in the food industry

Two typical AGV types for food industry customers are:

- Forklift or Pallet AGVs: Forklift AGVs, or pallet AGVs, are designed to handle palletized loads, and thus they are ideal for moving bulk quantities of food products to optimize storage space in warehouses. The AGVs are equipped with forks or clamps to lift and transport pallets safely.

- Conveyor AGVs: Conveyor AGVs are piggyback AGVs with an integrated conveyor belt that allow loads to be transferred directly from one location to another. These AGVs are commonly used in food processing and packaging areas to transport boxes, pallets, or other loads along a production line.

AGVs in the food industry are commonly equipped with advanced sensors, cameras, and navigation systems to improve protection for personnel and avoid damage to both products and other equipment in the facility. They can be integrated with warehouse management systems or other software to optimize operations and track inventory in real time. Additionally, AGVs designed for the food industry can feature surfaces that are easy to clean, such as stainless steel, to ensure compliance with hygiene standards.

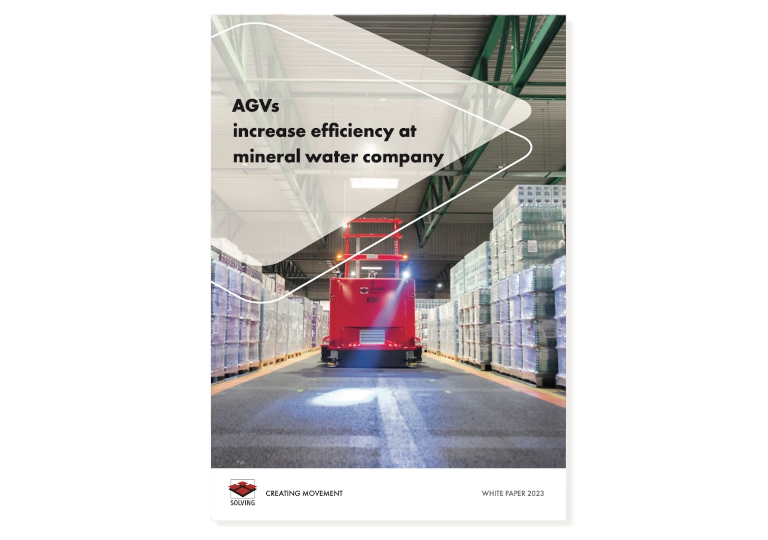

AGVs increase efficency at mineral water company

Learn how we helped a producer of bottled mineral water in becoming more efficient by automating the handling of the palletized water bottles in their warehouse

We appreciate the cooperation with Solving, firstly thanks to their good technical solutions, and secondly thanks to the attention they have given to our requirements

Reinhard Deimel, Supply Chain Manager at Vöslauer Mineralwasser GmbH

Some benefits of automation in the food industry

- Improved productivity: Automated Guided Vehicles can handle tasks efficiently and accurately 24 hours a day, thus reducing manual labor costs. This results in higher productivity in the warehouse operations.

- Enhanced food safety: Automation minimizes the risk of contamination associated with human error. It ensures proper handling, storage, and tracking of food products, reducing the risk of spoilage or incorrect storage conditions.

- Optimal space utilization: Automated Guided Vehicles can optimize space utilization in the warehouse. Using high-density storage, vertical space can be utilized efficiently, and thus the capacity of the facility can be maximized.

- Inventory management: Automation enables real-time tracking and monitoring of inventory. It provides accurate inventory data, improves stock rotation, and helps prevent stockouts or overstock situations.

- Traceability and compliance: Automated Guided Vehicles allow better traceability and compliance with food safety regulations. They can capture and record data throughout the handling process, making it easier to track products, monitor quality, and ensure regulatory compliance.

- Cost savings: By reducing manual labor costs, automation can lead to significant cost savings over time with a short payback period.

Would you like to discuss how we could help you achieve these benefits? Book a consultation with our experts, and we can discuss to find out how we could customize a solution suiting your specific requirements. Our team of experts will then analyze your warehouse operations and eventually propose a customized AGV system for you.

Don’t miss out on the opportunity to improve productivity in your warehouse operations. Contact us today to schedule a consultation and take the first step toward the benefits of automated handling in your food production facility.

Book a consultation

Book a consultation with us today and we will contact you to set up the meeting.

News

Contact us

Get in contact with us. We would like to hear from you.

Fill in the form or contact us directly.