Air Film Movers

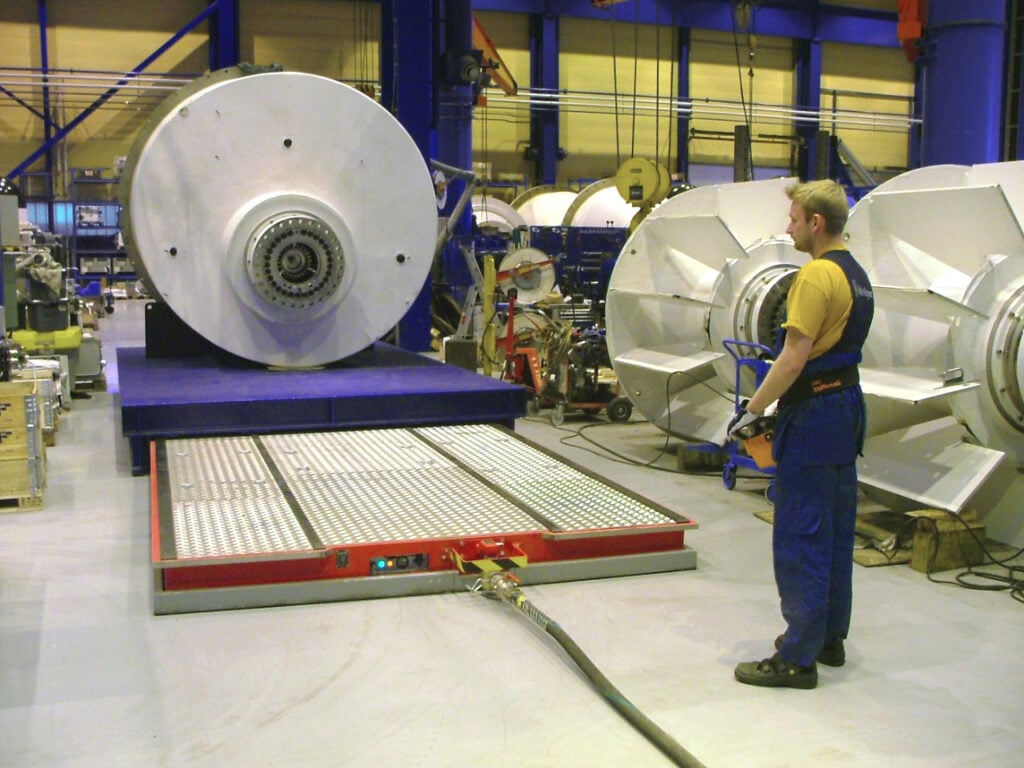

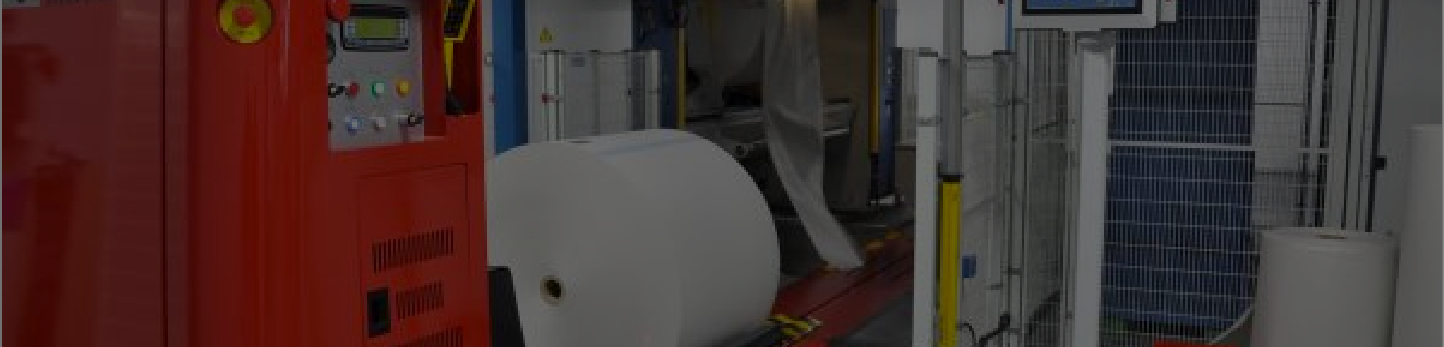

Solving Air Film Movers are designed for handling almost any type of load weighing from a few tons to a thousand tons or more and are mostly tailored to suit customer’s requirements. Air Film Movers are typically used in various industries for transporting heavy and bulky loads such as diesel engines, transformers, locomotives, vehicles, aircraft sections, paper rolls and containers. Custom-built platforms floating the loads on air is a flexible method of transporting heavy material within industrial facilities.

Typical applications of Solving Air Film Movers

The load to be transported is placed either directly on the Mover or on a load pallet, under which the Air Film Mover drives to collect the load. When in operation the Mover and load float on a thin film of air which provides virtually friction-free transportation and therefore causes no floor wear.

In most cases the Mover is controlled by a remote control unit, and only a single operator is required to move and supervise the movement of bulky loads.

When are Solving Air Film Movers a good choice?

Solving Air Film Movers are customized and therefore a good choice whenever critical customer requirements and specifications must be met. Air Film Movers are suited for indoor handling tasks over shorter distances, where high degrees of flexibility and manoeuvrability are important. The transport route can easily be changed at any time without modifications made to the building.

Solving Air Film Movers are a cost-effective solution for loads weighing 1000 tons or more, when compared to cranes for example. There are few alternative floor-based solutions that can offer the same capacities as Air Film Movers.

The low lifting height of the integral air bearings in combination with a low-profile Air Film Mover means that the total height of the handling equipment is very low. This makes Air Film Movers a good choice for bulky loads, such as large transformers, when the height of the handling system can be critical.

3 reasons why

1

High capacity

Solving Air Film Movers are a flexible solution for handling loads weighing 1000 tons or more.

2

Low point load

The point load applied to the floor is low because the load is spread over a large area, and there is almost no friction and therefore almost no floor wear.

3

Flexibility

Solving Air Film Movers are omnidirectional and can be positioned with millimeter precision. There is no need for fixed installations in the building, and transport routes can easily be changed.

FAQ

What kind of floor is suited for air bearings?

The floor is an essential component of air film technology and certain floor conditions must be applied to ensure efficient operation of an air film system. The ideal concrete floor is power-trowelled to achieve a flat papersmooth finish. Download our whitepaper below to learn all about floor requirements.

When do I choose between an AGV and a Mover on air bearings?

Generally speaking, AGVs are suitable for moving loads in a continuous 24/7 operation, whereas Air Bearing Movers are more suited to handling heavier loads, from a few tons to a thousand tons or more, less frequently and over shorter distances. Exceptions are always possible, so please contact our sales team for discussions about your specific requirements.

What advantages do Air Film Movers provide?

- Omnidirectional driving and precise positioning

- No floor wear

- Very quiet and smooth operation

- Cost-effective solution

- Easy manoeuvrability

- No fixed installations such as rails in the floor required

- A clean and safe working environment

- Low-profile equipment and low lifting height

What are the floor requirements for Air Film Movers?

The floor is an essential component of air film technology and certain floor conditions must be applied to ensure efficient operation of the air film equipment. The ideal floor must be flat, free of steps and cracks, and nonporous with a paper-smooth surface.

Flatness

When the load is floating on air, the friction between the floor and the air bearing is very low. With an uneven or inclined floor, the load can start moving due to gravitational forces and therefore the flatness must meet certain requirements. The overall levelness of the floor becomes more important when handling heavy loads.

Free of steps

A good floor is free of steps or cracks in the floor, although minor imperfections can be filled and ground or faired in.

Airtight floors

A non-porous, airtight floor surface is needed for an air film to be formed between the floor and air bearings. Small joints, cracks and damage can however be repaired with a smooth filling material.

Paper-smooth surface

A power-trowelled dense concrete surface is usually excellent if the trowelling has resulted in a light-reflecting paper-smooth finish.

Occasional moves

For occasional moves a substandard floor can be improved using thin sheet steel or PVC.

What compressed air supply is required?

The air supply pressure and volume are critical for air bearing applications. Specific requirements should also be considered regarding air quality, piping material and dimensions to ensure correct operation with a minimum of maintenance. Occasional moves using rig sets are less affected by issues caused by air supply problems than an Air Bearing Mover with integral controls and air-powered drive units.

Learn more about floor requirements

Want to know more about Air Film Movers and floor specification? Please download our whitepaper.

Do you need a bespoke, tailored Air Film Mover to meet your specific handling requirements?

Solving Air Film Movers suit customers requiring more than a standard, off-the-shelf solution.

News

Contact us

Get in contact with us. We would like to hear from you.

Fill in the form or contact us directly.