17.12.2021

Solving awarded contract for Posiva’s ONKALO® Repository

Solving is proud to announce that we have been awarded a contract for an AGV system for Posiva’s ONKALO® Repository, following a long period of cooperation between Solving and Posiva dating back to 2012.

Electricity produced at nuclear power plants generates radioactive nuclear waste, and the waste must be taken care of in a way that does not harm the environment. Posiva is the first company in the world to build facilities for the safe final disposal of spent nuclear fuel and Solving will contribute to this impressive achievement with an AGV system for the transportation of disposal canisters in the repository.

Solving was approached by Posiva in 2012 with the challenge to study the material handling aspect of the repository. This pre-engineering study resulted in the manufacture of a pair of prototype Solving Movers for handling disposal canisters. The prototypes were thoroughly evaluated by Posiva and further discussions between Posiva and Solving resulted in an agreement for a final automated transport solution, which is now under construction.

“We are honoured and privileged to be part of such a pioneering project”, says Sales Manager Andreas Backman at Solving.

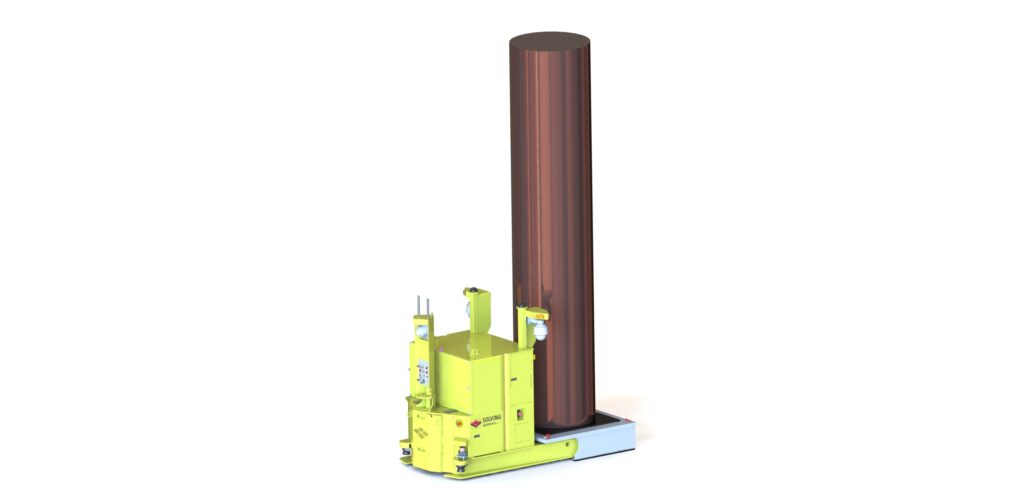

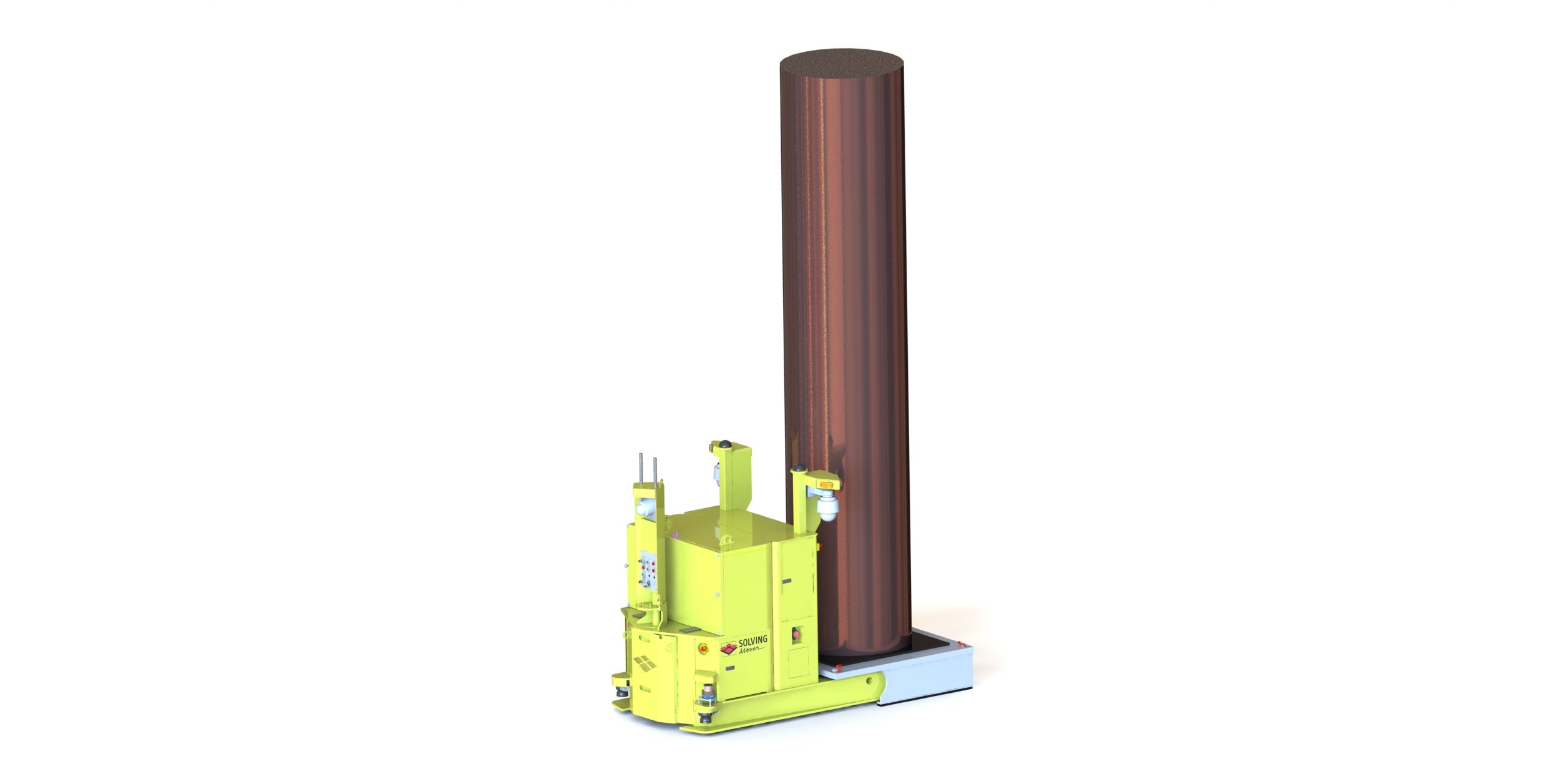

Customized Solving Movers

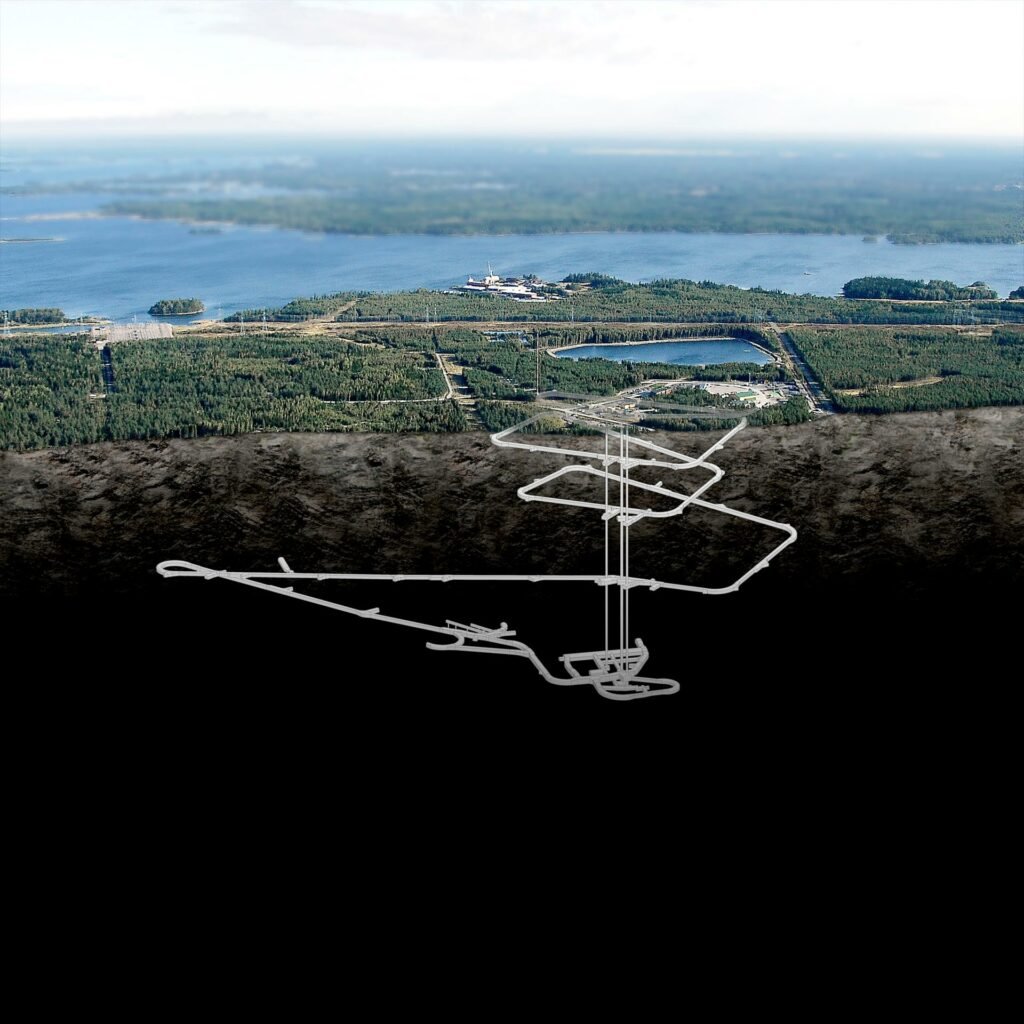

Solving will install an AGV (Automated Guided Vehicle) system consisting of two Solving Movers, which are designed for moving disposal canisters with spent nuclear fuel, at Posiva’s disposal facility in Olkiluoto, western Finland. The AGV Movers automatically move the canisters along predefined routes in the transport layout using an optical laser scanner reading reflectors on the walls along the route to navigate.

Practically all Solving Movers are customized to suit customer-specific and environmental requirements, and these AGVs also have special features.

Andreas Backman

Special features of the AGV Movers at Onkalo®

The operation of the Movers is monitored remotely from a control room at the disposal facility where an operator gives transport tasks to the Movers. They can then be followed via a live video feed from onboard and fixed cameras mounted in various locations in the facility to ensure maximum safety of operations. Additionally, in case of a failure, a towing tool can be connected to one AGV to bring back the failed one for repair.

The Movers operate in two areas: the Encapsulation Plant and Disposal facility.

Encapsulation plant Mover

One Mover will operate in the above-ground Encapsulation Plant. Once a completed canister comes out from the encapsulation process, the Mover brings a pallet in front of the transfer trolley to receive the canister, which is then placed on the pallet and transported by the Mover either directly into a lift or to a buffer storage.

Disposal facility Mover

The second Mover will operate in the ONKALO® disposal facility located at a depth of more than 400 meters, where it will transfer canisters both between the lift and canister storage and between the canister storage and installation vehicle.

The Mover picks up a canister from the lift and transports it to a pre-defined location in the canister storage, where an operator drives it manually to a desired storage position.

The Mover is also used for retrieving a selected disposal canister and pallet from the storage area, and for carrying them to an auxiliary canister hoist. Once the canister has been passed over to an installation vehicle, the Mover picks up the empty pallet from the hoist and moves it either to the lift to return it back to the encapsulation plant or back to the canister storage area.

The trial run of the final disposal will take place in 2023.